What makes a stretch wrapping machine essential for manufacturers

What makes a stretch wrapping machine essential for manufacturers

Blog Article

Enhance Your Packaging Refine With a Trusted stretch wrapping machine for Ideal Efficiency

In the complicated globe of logistics, a reliable packaging process is an important aspect that can considerably influence a company's lower line. The consolidation of a reputable stretch wrapping machine not only enhances performance however additionally makes sure the honesty of products throughout transit - stretch wrapping machine.

Recognizing the Function of a stretch wrapping machine in Packaging

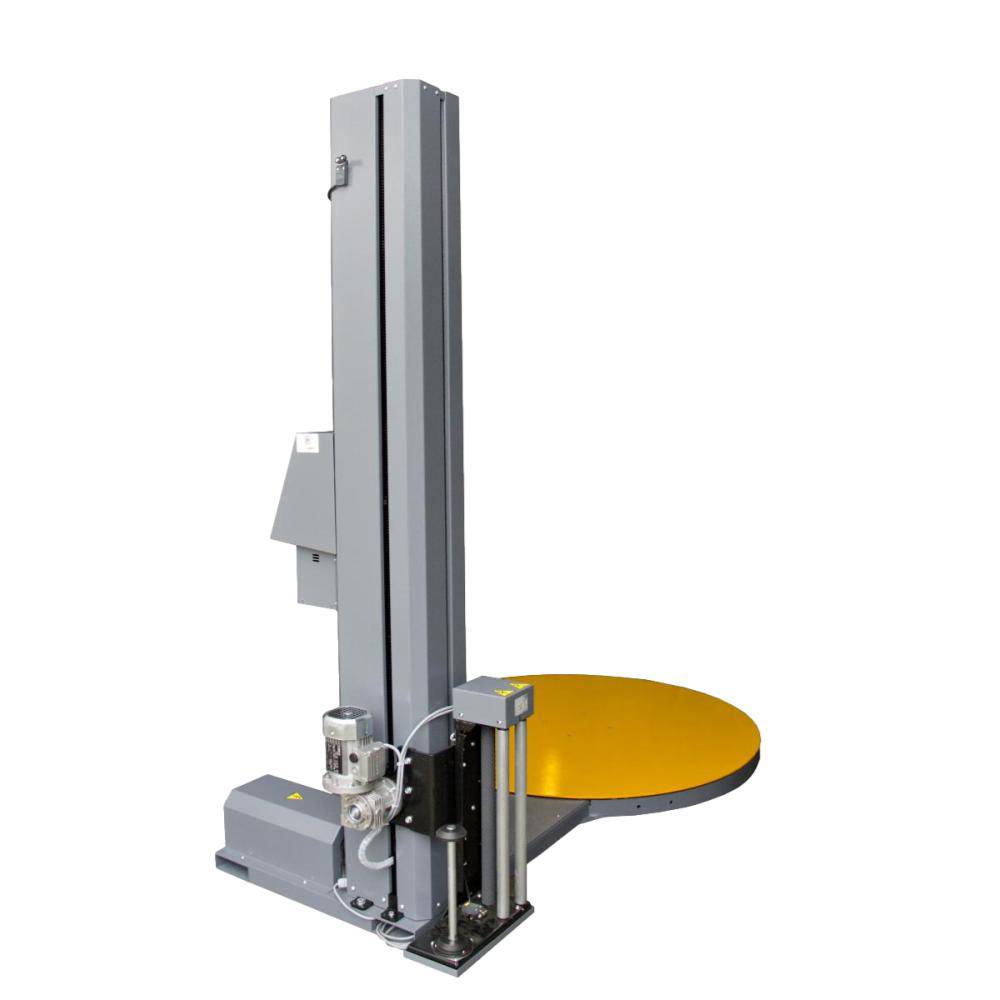

Making certain product safety and security during transportation, a stretch wrapping machine stands as an essential possession in the packaging industry. Its key duty focuses on encapsulating things in a safety layer of movie, consequently protecting item integrity and lessening damage threats during transportation.

The maker's procedure is detailed yet efficient. Item are put on a revolving base while the movie is unraveled from a set roll. As the turntable rotates, the movie is applied evenly over the things, making sure full insurance coverage.

This machine's importance extends beyond plain wrapping. stretch wrapping machine. It boosts the stacking security of goods, lowering the possibility of crashes. Further, it safeguards things from dirt, dampness, and various other environmental aspects, maintaining their quality until they reach the customer

In significance, a stretch wrapping machine is an indispensable device for organizations looking for to enhance their product packaging process, safeguard their products, and streamline their logistics procedures. Its role is important to the efficient and effective performance of the modern product packaging sector.

When Picking a stretch wrapping machine, key Attributes to Consider.

When selecting a stretch wrapping machine for product packaging functions, a number of essential attributes warrant factor to consider. These include examining the device's efficiency, understanding its tons capacity, and assessing its durability and upkeep needs. An educated choice joints on a detailed evaluation of these factors.

Although performance might not be the very first point you think of when considering stretch covering devices, it is a necessary element that can considerably influence your product packaging procedure. An effective device can considerably lower waste, lower costs, and enhance efficiency. When reviewing performance, think about the machine's speed. A quicker maker can wrap much more plans in much less time, increasing your procedure's outcome. Check for programmable settings, which can personalize the covering procedure to fit various products, reducing unnecessary use of materials. Additionally, a reliable maker needs to require marginal maintenance, guaranteeing continuous operation without constant disturbances. The equipment's energy intake is an additional essential aspect, as a device that makes use of less energy can cut running costs. Remember, a reliable machine warranties optimum performance.

The Influence of a Reputable stretch wrapping machine on Efficiency Levels

Investing in a dependable stretch wrapping machine can dramatically increase productivity levels in a product packaging procedure. These equipments automate the wrapping procedure, permitting effective and constant performance that exceeds her comment is here manual covering techniques.

A trustworthy machine minimises downtime caused by mechanical failures or upkeep requirements. Premium stretch wrapping makers additionally have flexible setups for different item kinds.

Additionally, these equipments require much less human intervention, liberating employees to concentrate on various other essential tasks. This optimization of human sources can lead to a rise in overall operational performance.

Basically, a dependable stretch wrapping machine is an important financial investment that can boost productivity levels in a product packaging procedure, providing significant benefits in flexibility, effectiveness, and resource exercise.

Ways in Which a stretch wrapping machine Minimizes Waste

A stretch wrapping machine's function find out this here in waste decrease is significant and complex (stretch wrapping machine). Not only does it reduce product usage by efficiently wrapping items, but it also safeguards items from damages throughout handling and transportation. This dual advantage outcomes in noteworthy expense savings and advertises sustainability in the packaging process

Lessening Material Use

Expense and Time Savings: The Economic Advantages of a stretch wrapping machine

Moreover, the maker's constant covering strategy minimizes product damages, lowering replacement expenses and boosting client complete satisfaction. Making use of a stretch wrapping machine likewise brings about a more predictable budgeting process, as the quantity of stretch film used per pallet is consistent, unlike manual covering which can vary significantly.

Ultimately, the advancing savings in labor, products, and prospective item loss make the first financial investment beneficial. In the long-term, organizations can attain significant economic benefits by incorporating a stretch wrapping machine into their product packaging process.

Conclusion

Although effectiveness could not be the very first point you believe of when thinking about stretch wrapping machines, it is an essential aspect that can considerably affect your packaging process. The maker's power consumption is an additional essential variable, as a device that utilizes less power can cut running costs. Furthermore, a machine sustained by a detailed guarantee and exceptional customer solution can ease prospective difficulties in keeping the equipment's ideal efficiency.To recognize the ways in which a stretch wrapping machine minimizes waste, one have to initially consider the ingenious style of these devices. In this means, stretch wrapping makers not just boost the top quality of product packaging but likewise promote a more environmentally-friendly and effective process, showing their important role in contemporary product packaging operations.

Report this page